INTRODUCING THE

PIPEFAB™

WELDING SYSTEM

The Ideal Setup for Pipe

and Vessel Fabrication

From machine design to arc performance, no detail was overlooked in delivering a complete, customer-driven system that lets your shop focus on what matters most - making high quality root-to-cap welds, faster and easier.

Features

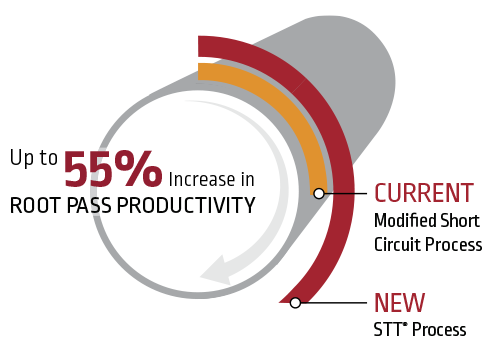

Breakthrough Arc Performance

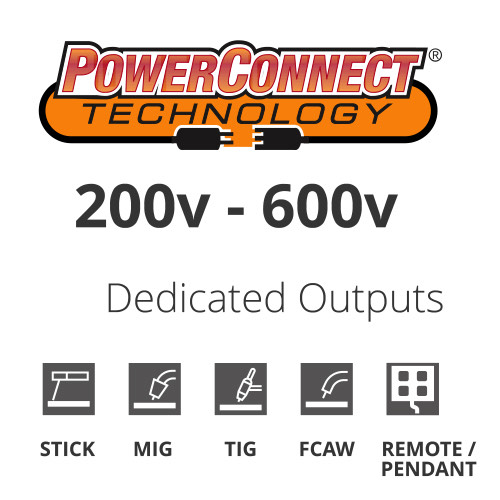

From root, to cap, to final fit - the PIPEFAB™ system has you covered with weld modes that have been fine-tuned to deliver breakthrough arc performance specifically for pipe and vessel fabrication.

Straightforward & Simple

Developed to be the fastest, smartest and easiest solution on the market, the PIPEFAB™ system delivers straightforward and simple digital control with one-click process selection.

Industry-Driven Design

Like the name says, the PIPEFAB™ system was developed specifically for pipe and vessel fabrication. With its Ready-to-Run™ design, every detail was considered in creating the ultimate setup for the pipe and vessel industry.

Trusted Expertise & Support

Whatever challenge you may have, wherever in the world it may be, Lincoln Electric is here to help with proven industry knowledge and support.

TEST Results Disclaimer:

Test results for mechanical properties, deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means the suitability of any welding consumable and procedure before use in the intended application

GAME-CHANGING PERFORMANCE

AND SIMPLICITY

The Next Generation of Simplicity and Control

With the industry’s leading user interface, the PIPEFAB™ Welding System ushers in the next generation of intelligent, operator-focused machine control that makes interaction as straightforward as possible.

- Simple, straightforward navigation

- 20+ language preferences for true global capability

- Parameter restrictions / range limits

Request Information On PIPEFAB™

Please complete the form below for more information on PIPEFAB™.