Collect Data. Create Action.

Turn meaningful data into action and see a true picture of your operation's welding cost, quality, and performance with CheckPoint® Weld Data Monitoring Software.

Weld Data Monitoring Made Easy

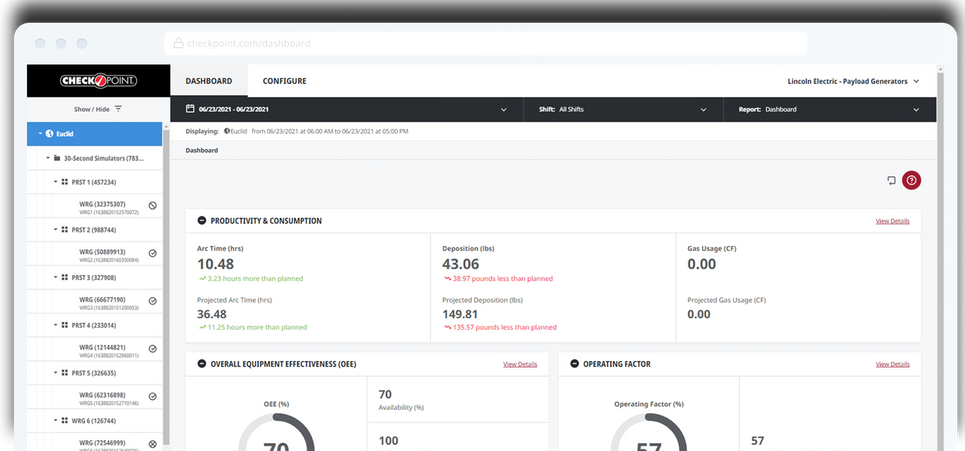

Improved dashboards provide essential, real-time weld data - making it easier to see performance metrics and trends that impact welding productivity and efficiency.

New reporting helps managers see throughput trends that impact productivity and efficiency

New user experience design makes it easier for managers to access reports

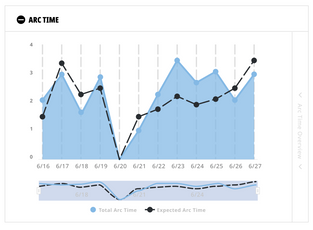

Productivity Metrics

Monitor and forecast arc time, deposition, and more.

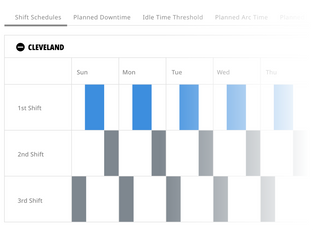

Shift Planning

Visualize shift schedules and plan for downtime.

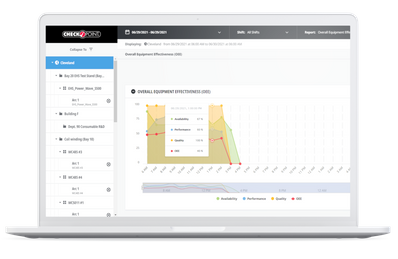

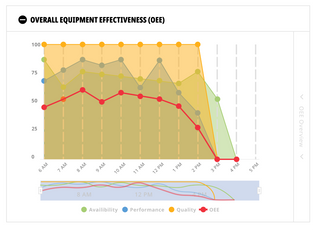

Overall Equipment Effectiveness (OEE)

Monitor OEE in real-time for a true picture of productivity

Data-Driven Quality Assurance

Provides an immediate picture of weld quality across the plant

Set parameter limits and track key weld quality metrics down to the station level; manual or robotic

Virtual paper trail makes it easier for management to identify the root of quality issues

How It Works

Secure, cloud-based platform allows you to easily connect and visualize weld data anywhere, at any time.

Standard, embedded feature with no hidden costs

No software installation - easily access on a web browser

Simply connect your machine to an existing network via ethernet or wi-fi

Standard feature on Power Wave® & PIPEFAB™ Advanced Welding Platforms

Partners in Your Data Journey

With decades of weld data expertise, Lincoln Electric provides the trusted support you need to turn your weld data into action.

From set up, to implementation, to scaling CheckPoint across your entire operation, we are here to help.

Discover The Truth in Your Welding Today

Fill out our brief form to request a demo, or receive a weld data assessment for your operation